Type Of System

VNA, Pick Tower

Location

Wetaskiwin, Alberta

Gallery

As a Western Canadian retail cooperative, this company is a crucial distribution hub for dealer-owned stores and online order fulfillment. Challenges emerged as the business landscape evolved, including increased SKU inventory and a higher demand for rapid order processing. Seeking solutions, they partnered with North American Storage to craft a tailored storage strategy. This collaboration addressed the need for efficient pallet storage, optimized pick locations, and refined internal logistics for smooth item movement within the facility.

Challenges Faced

The company faced several challenges. The increasing SKU inventory and order fulfillment requirements strained the existing storage space. The need for pallet storage and designated pick locations was crucial.

Simultaneously, the client desired to construct a 60-foot-tall building and utilize the total height. Achieving this vision required a precise level floor and tight tolerances for manufacturing and installation. The client also retained a conveyor system that needed to be incorporated into the design and facilitate integration with the existing ceiling-mounted system. Addressing a solution for a single row of racking secured to the unusual building shape became imperative.

Solutions

The selective racking system was implemented to meet the specified 57-foot storage height requirement, offering 13,977 pallet positions across ten levels, each capable of holding 5000 lbs. An angled wall with single deep selective racking required collaboration with the building engineer to stabilize the frames with the exterior building structure.

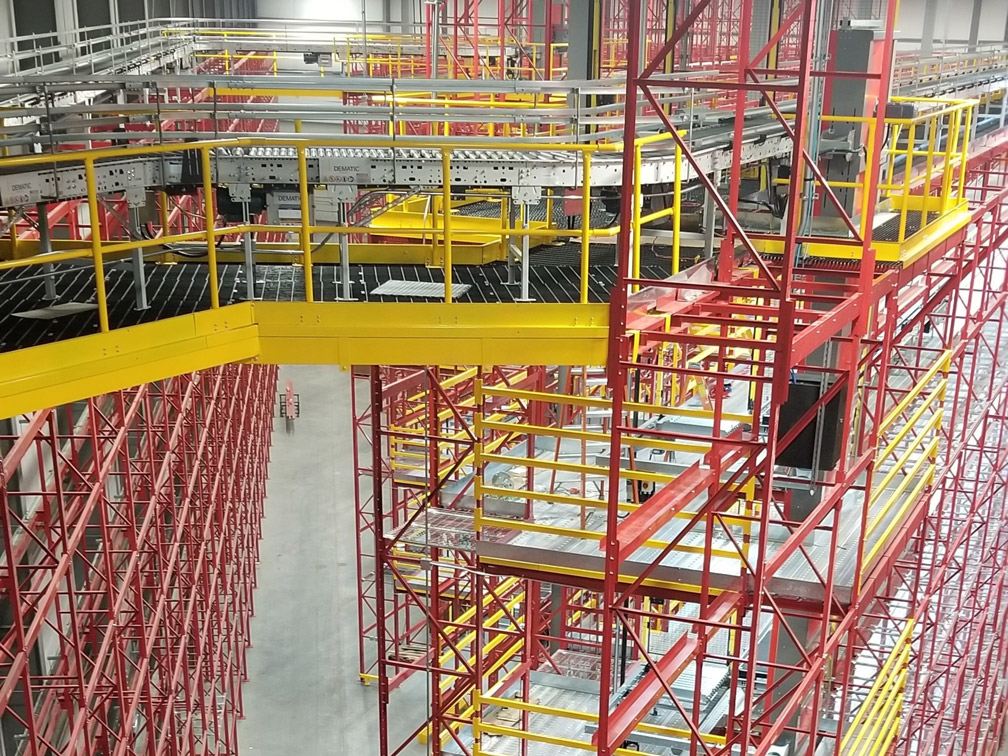

Storage platforms were incorporated to streamline pallet picking operations by utilizing a pair of five (5) level towers. These towers significantly enhanced the capabilities of the storage system, providing ample space for pallet storage and improving accessibility for items at various levels within the facility. These systems enabled full pallet loading from the outside aisle and picking access from within the tower. The aisles were designed to accommodate a powered conveyor and room for associates to move quickly between levels and within the structure.

- Elevator Integration for Item Movement:

Integrating two elevators per pick tower was a pivotal solution, efficiently transporting totes between different levels within the structure. This cohesive setup ensured a smooth and effective picking of goods, ultimately expediting the delivery process flow to the shipping area with precision and consistency.

- Comprehensive Project Management:

The comprehensive oversight spanned every project phase, encompassing design, permitting, manufacturing, and installation. This thorough management ensured a cohesive and integrated approach from conception to execution. Moreover, close collaboration with key stakeholders, including the building’s general contractor, conveyor supplier, and lift truck manufacturer, was integral. This team collaboration aimed to ensure the effortless functionality and harmonious integration of all system components, guaranteeing the project’s success.

Results

By implementing a tailored storage strategy featuring a Structural Very Narrow Aisle (VNA) system, elevators for item movement, and meticulous project management, the company successfully optimized storage, expedited logistics, and facilitated proficient order processing. This collaborative endeavour showcased the commitment to meeting client needs and demonstrated the industry-leading standards maintained by North American Storage in delivering exceptional solutions.

Ready to upgrade your storage systems and streamline operations? Partner with North American Storage for custom storage solutions. Our expertise spans conception to execution, ensuring a flawless integration of innovative systems that enhance storage capacity and expedite order processing.

Contact us today to start optimizing your inventory management!