- North American Steel (Whitby, ON):905-668-3300

- | North American Storage (Nisku, AB):780-955-2444

- , (Calgary, AB):587-327-8944

Industries

- Automotive

- Building Products & Lumber

- Cold Storage & Freezer

- E-Commerce

- Electronics & Electrical

- Food & Beverage

- Furniture & Appliance

- Hardware & Plumbing

- Manufacturing Center Rack

- Metal Fabricating / Mining

- Outdoor Storage Racking

- Petro Chemicals

- Retail Logistics Racking

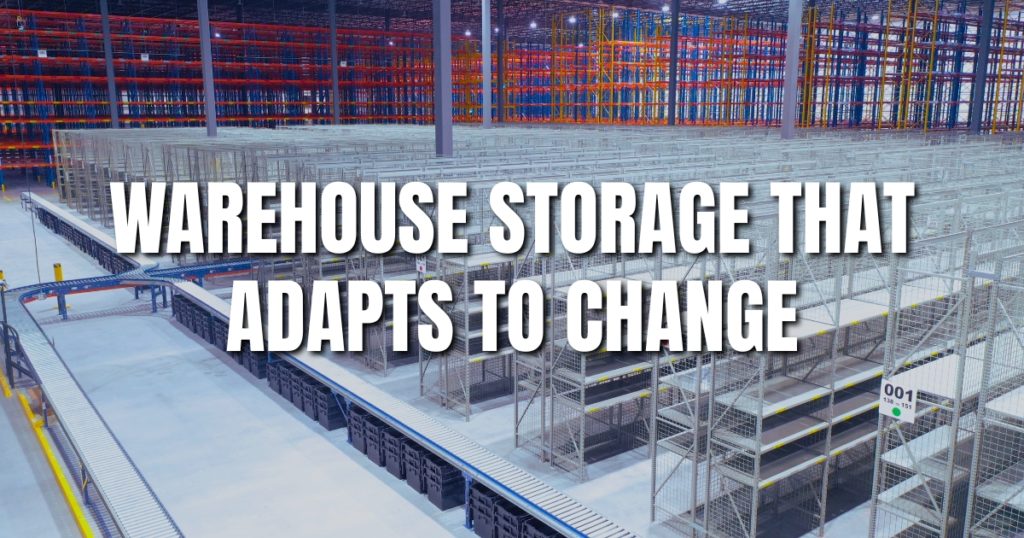

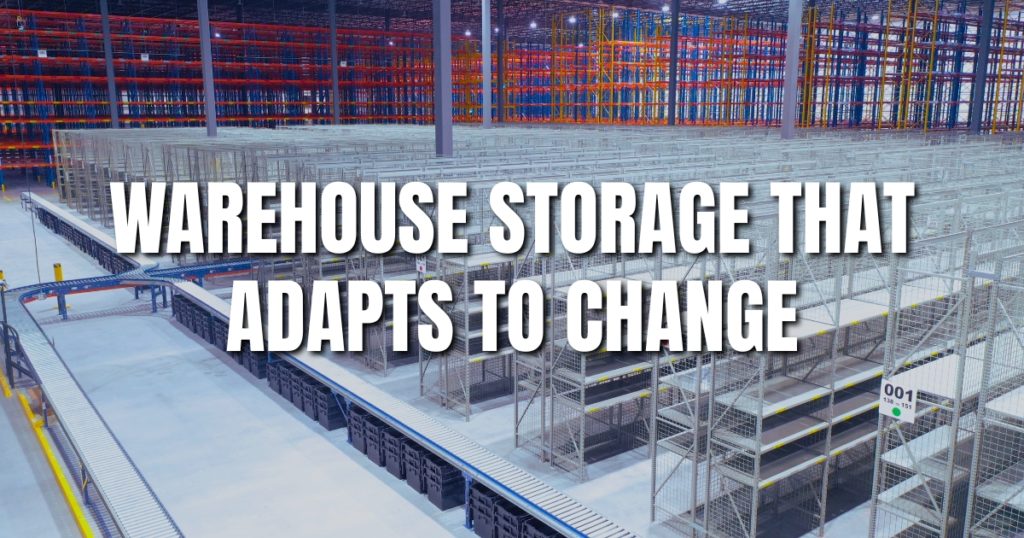

- Warehouse Storage

- Wholesale & DC Racking

- Systems

- Products

- Services

- Resources

- Contact us

About us

- Request a Quote

- Careers

Discover the top warehouse trends for 2026, from AI and automation to safety, sustainability, and flexible storage solutions.

A growing mining company transformed its parts storage with a custom two-level mezzanine, tripling capacity and improving safety.

Learn how Canadian DCs can adapt warehouse storage to tariff-driven inventory shifts with professional racking solutions.

Learn about the essential role engineering plays in designing efficient and safe racking systems.

Explore our racking vs. shelving guide to choose the best warehouse storage.

Discover how mezzanine storage platforms maximize warehouse space.

Discover the top warehouse trends for 2026, from AI and automation to safety, sustainability, and flexible storage solutions.

Learn how Canadian DCs can adapt warehouse storage to tariff-driven inventory shifts with professional racking solutions.

Learn about the essential role engineering plays in designing efficient and safe racking systems.

Explore our racking vs. shelving guide to choose the best warehouse storage.

Discover how mezzanine storage platforms maximize warehouse space.

Discover the top factors clients prioritize when choosing a racking supplier.

A growing mining company transformed its parts storage with a custom two-level mezzanine, tripling capacity and improving safety.

Discover how strategic racking design and phased installation powered 18 Wheels Logistics’ expansion into a 220,000 sq ft live facility in Eastern Canada.

Discover how early involvement by North American Steel optimized distribution centers in Chicago and Los Angeles, enhancing efficiency, safety, and compliance. Read the full case study.

See how NASECO's tailored racking improved storage at a Richmond, BC, bottling plant.

Custom racking solutions to integrate with a variety of electrical solutions - from automation, datacom, and more.

Boosting Efficiency & Brand for an Edmonton Beverage Distributor with Smart Storage Solutions.