Type Of System

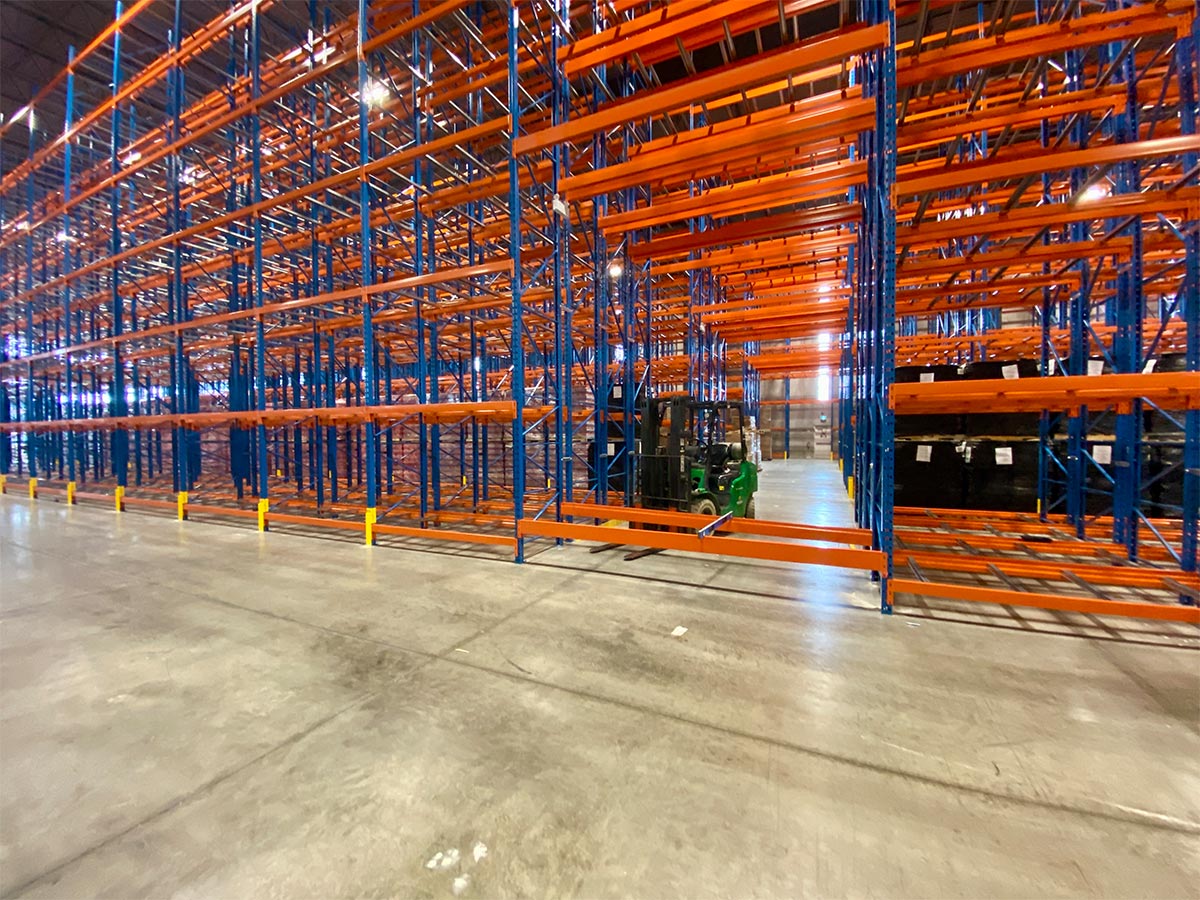

Double Deep Racking

Location

Brampton, Ontario

Gallery

Setting out to expand their national footprint and strengthen service in Eastern Canada, 18 Wheels Logistics sought a warehousing solution that could support their timeline, budget, and evolving customer needs. The result was a new 220,000 sq ft facility in Brampton, Ontario. Serving a diverse client base across beverage, furniture, and other sectors, the new space required high-density pallet storage that would integrate smoothly into active operations and allow for reconfiguration as SKUs changed.

Challenges Faced

Live Site Conditions:

The Brampton site was already live when the project began, with operations underway and bulk storage in use. To stay on schedule and within budget, installation needed to be staged around product movement and day-to-day warehouse activity without restricting access to inventory or disrupting fulfillment.

Customer-Specific Storage Needs:

As a 3PL managing varied client inventory, including food-grade products and furniture, 18 Wheels needed a system that balanced selectivity with high density. Flexibility was essential, especially for inventory with expiry dates and shifting pallet requirements.

Engineering considerations:

With the goal of maximizing performance without unnecessary material spend, we needed to carefully account for seismic codes, which would impact frame design and project cost.

Solutions

Double Deep Racking with Operational Flexibility:

To address density and selectivity, North American Steel designed a double deep system—ideal for storing high volumes while still allowing for reliable inventory access. This configuration is especially well-suited to the food and beverage sector, where stock rotation and pallet tracking are critical.

We also engineered the layout for future adaptability. As needs evolve, adjustments can be made quickly through our in-house engineering team.

Phased Installation Around Active Operations:

To align with capital planning and immediate operational needs, we took a phased approach to installation: Phase 1 at 20,000 pallet positions, and Phase 2 adding another 10,000. Given the live environment, the installation was designed to keep operations moving. Specific zones were isolated for racking while adjacent areas remained operational, allowing 18 Wheels to continue moving and fulfilling product.

The installation was completed in under eight weeks—a notable achievement given the size of the system and the added challenge of working within a live warehouse, highlighting the value of precise coordination.

Cost-Effective Seismic Engineering:

Rather than rely on default seismic values, 18 Wheels provided us with a geotechnical investigation report containing a defined average shear-wave velocity (Vs₃₀) reading (a measure of ground stability across the upper 30 meters of soil).

With that information, NAS was able to engineer the system to a lower seismic site class, resulting in lighter frames and meaningful cost savings without compromising structural integrity. This approach helped reduce material cost significantly, while maintaining structural integrity and code compliance across the racking system.

Value-Engineered Custom Brace Pattern

We optimized the frame with a customized, 24-inch brace pattern at the base—eliminating the need for more expensive double-posting, with the design tailored to the project’s specific seismic classification. Based on the presence of a bottom beam, 18-inch clip-on post guards were installed, extending higher up the frame to ensure coverage where contact is most likely.

Results and Impact

Phase 1 of the racking system delivered 88,740 sq ft of pallet storage, giving 18 Wheels a robust foundation as it scales operations in Eastern Canada. The system is designed for adaptability, with Phase 2 and reconfiguration options already accounted for in the layout.

By using the client’s geotechnical report and responding quickly to evolving site needs, we reduced material costs and kept the project on schedule, resulting in a system designed to support fast-paced growth. Projects like this demonstrate how tailored engineering and thoughtful phasing can support both immediate operations and long-term growth.

We continue to deliver systems that fit the way today’s dynamic industries operate—efficient, adaptable, and built to keep up with change. If you’re planning a new facility or working through an upgrade, we can help you build a solution around your unique space, timeline, and goals.