Type Of System

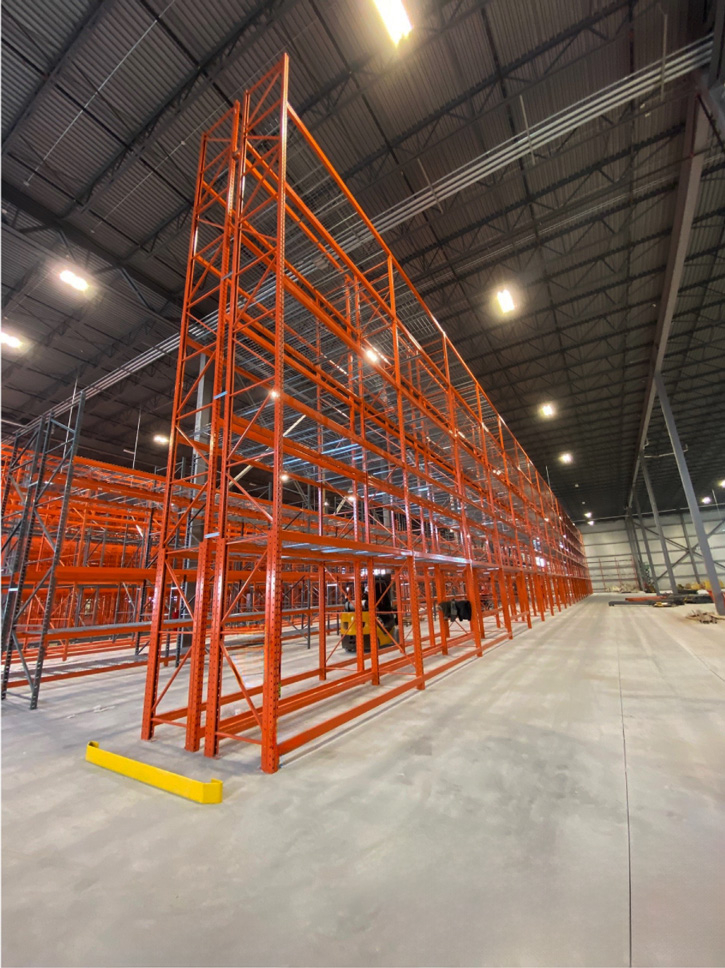

Selective VNA Racking

Location

Pickering, Ontario

Gallery

In the fast-paced world of retail, efficient logistics and optimized storage solutions are crucial for maintaining a competitive edge. When a prominent furniture, appliances, and electronics retailer was faced with the critical task of relocating one of its distribution centers, they turned to North American Steel for a pallet racking system that would optimize storage capacity and facilitate a seamless move.

Challenges Faced

1. Relocating Facility Under Tight Deadline:

The client had to execute the facility relocation within a tight deadline. It was crucial to minimize operational downtime and ensure a smooth transition to the new location.

2. Integrating Old Racking Components with New Ones:

The client’s existing facility had a mix of racking components from different vendors. Integrating the old racking with new components posed a challenge, requiring careful assessment and customization to ensure compatibility and optimal performance.

3. Diverse Range of Products:

The client’s inventory consisted of products with varying weights and dimensions, necessitating a pallet racking solution capable of accommodating these diverse requirements.

4. Increasing Capacity and Optimizing Storage:

The previous facility suffered from overcrowding and limited storage capacity. The client needed a solution that would significantly increase storage space while optimizing accessibility and retrieval processes.

Solutions

NAS provided comprehensive solutions to address the challenges faced by the client:

1. Efficient Project Management and Timely Execution:

NAS’s experienced team ensured the smooth transition of the facility, coordinating closely with the client and other contractors. This ensured minimal disruption to the client’s operations and allowed them to resume business quickly.

2. Meticulous Integration of Old and New Components:

An assessment of the existing racking components was conducted by NAS’s design and engineering experts. Through careful examination, they identified undamaged components that aligned with the required specifications. These compatible components were seamlessly integrated with new ones, ensuring a harmonious and functional pallet racking solution. By leveraging over 20% of the project’s racking material from the client’s original warehouse, NAS not only upheld the system’s structural integrity but also delivered substantial cost savings.

3. Tailored Design for Diverse Product Range:

A customized pallet racking solution was designed to cater to the client’s wide array of products. Wire mesh decks were a key feature of the design, offering optimal fitment for products with varying weights and dimensions while ensuring compliance with stringent fire code regulations. These decks allowed for better sprinkler system penetration, enhancing fire suppression capabilities compared to solid shelving options. Rated at 2,500 LB UDL, the wire mesh decks provided strength and durability for the client’s storage needs. Safety bars strategically placed in the middle of each beam reinforced the system’s stability.

4. Maximizing Capacity and Efficiency:

To address the client’s need for increased capacity and optimized storage, NAS implemented a tailored selective Very Narrow Aisle (VNA) racking system. By introducing 66″ aisle widths instead of the previous 72″, the warehouse space was maximized. Additionally, the system’s beam levels were increased from three to five, reaching a height of 20 feet. This expansion significantly enhanced the storage capacity, eliminating overcrowding and improving the efficiency of storage and retrieval processes.

Summary

NAS successfully addressed the challenges faced by the client during their facility relocation and implemented a tailored pallet racking solution. By integrating old and new components, accommodating a diverse range of products, and increasing storage capacity, NAS revolutionized the client’s warehouse efficiency and productivity. The customized selective VNA racking system, combined with careful project management and engineering expertise, resulted in tangible benefits. The client now enjoys increased storage capacity with over 6500 pallet positions, a total distribution center area of 120,000 square feet, and enhanced warehouse operations.

Contact NAS today to discover how our customized pallet racking solutions can transform your warehouse and optimize your storage capabilities.