Systems > Racking Systems > Dynamic Racking > Pushback Racking

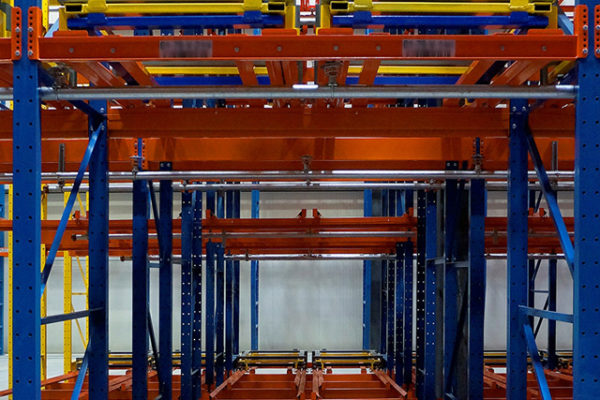

Pushback Racking

Advantages

When it comes to optimizing your warehouse’s storage capacity and improving inventory management, Pushback Racking is a versatile solution that maximizes both space and efficiency. This robust system offers several key advantages that make it an ideal choice for industries seeking vertical storage solutions.

Key Features & Benefits

- Pushback Racking combines the increased pallet counts of Drive-In systems with quicker access to rear pallets, enhancing operational efficiency.

- Operates on the Last-In, First-Out (LIFO) principle, with each lane flowing independently and accommodating multiple products per bay.

- Ideal for depths ranging from two to six pallets, often installed against a wall or in back-to-back rows.

- Versatile design for various pallet sizes and weights.

Efficient Inventory Management

Pushback Racking excels in efficient inventory management with its Last-In, First-Out (LIFO) principle within each lane. This system ensures that the latest arrivals are readily accessible, thanks to multiple pallets stored on a gravity-fed cart system. Additionally, when grouped by date, this racking system allows for the First-In, First-Out (FIFO) rotation of SKUs by lane, further enhancing inventory efficiency.

High-Density Storage with Selectivity

Pushback Racking is renowned for its space-efficient design, allowing you to store more pallets in the same footprint compared to other rack systems. Its height is only restricted by the maximum lift height of your lift trucks, allowing you to fully utilize your vertical space.

Additionally, it provides a higher level of selectivity compared to other dense storage systems like drive-in racks. With pushback racking, you can access multiple pallets within the same aisle, enabling quick and easy retrieval of specific products without having to move other items. This selectivity is vital for industries where inventory turnover and efficient stock rotation are crucial.

Customizable Depths and Adaptable Layouts

Ideal for depths ranging from two to six pallets, Pushback Racking is highly adaptable and can be installed against a wall or in back-to-back rows. Its flexibility ensures that building columns do not interfere with your packing aisles, offering tailored solutions for your specific needs.

Versatile Applications of Pushback Racking

Pushback Racking is versatile, making it ideal for Automatic Retrieval Systems, integration into Pick Towers, and Rack-supported buildings. It enhances automation possibilities and accommodates a variety of pallet sizes and types with full-frame Trolley Carts. This adaptability is a significant advantage for businesses with diverse product lines or changing storage requirements. Whether you are handling lightweight goods or heavy-duty materials, this racking system can be tailored to suit your specific needs.

Quick Installation and Adaptability

Installing Pushback Racking is a straightforward and efficient process, which means you can get your storage solution up and running quickly. Moreover, it offers adaptability to evolving business needs. As your inventory or storage requirements change, the racking can be easily reconfigured or expanded to accommodate those changes, reducing the need for costly system replacements.

Durability and Safety

Only the front beam and rack frames are exposed to lift truck impact, reducing potential damage and maintenance costs. Aisle frames can be reinforced to promote safer forklift movement and overall warehouse safety.

In summary, Pushback Racking is a high-density storage solution that combines space efficiency with selectivity, making it an excellent choice for industries looking to maximize their warehouse space and streamline inventory management. Its versatility, quick installation, and adaptability make it a cost-effective investment for businesses of all sizes.

Unlock the full potential of your warehouse space with a racking system from North American steel. Request a quote or speak to our experts for a tailored solution to optimize your storage operations.