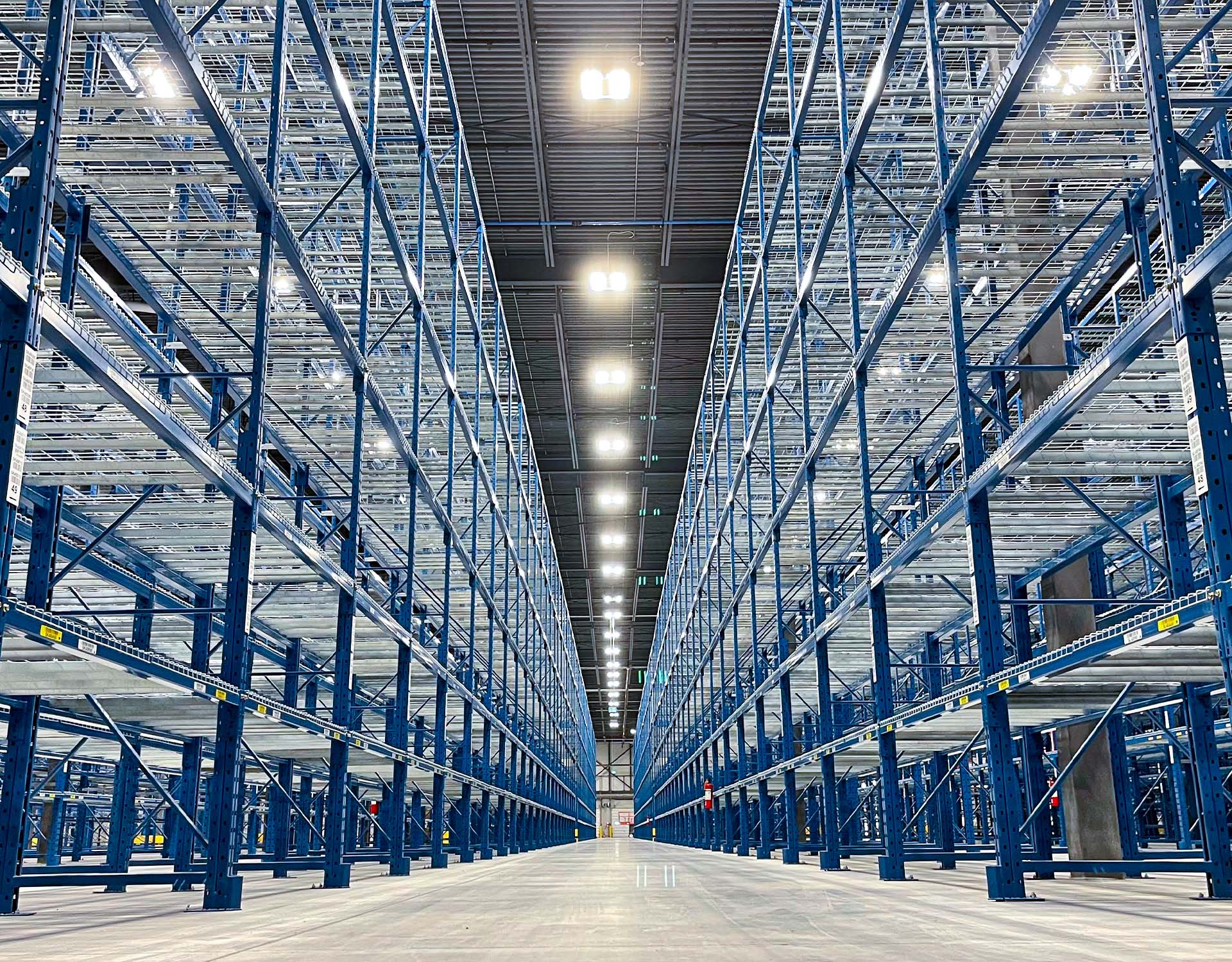

Type Of System

Selective Pallet Racking

Location

Guelph, Ontario

Gallery

There is no question that industrial storage space is becoming more limited and sparse across North America. With this restricted availability, businesses are forced to rethink traditional warehouse models, and have to start considering all aspects of their storage areas. Warehouse managers must also understand how critical it is to utilize the existing height in their warehouses, and how doing so truly optimizes their storage solutions.

In the preliminary stages of any racking project, we at NAS (North American Steel) take a comprehensive review of all the customers, and their businesses workflow to fully understand their needs. Other considerations we take into account can be

- How their business operates

- Any restraints they may have

- The available overall budget

From here, our designers and engineers are able to tailor a storage system that meets and exceeds all specified requirements. In this case, our sales team at NAS worked with a direct-to-consumer e-commerce retailer who was faced with a problem many warehouses alike are facing, limited storage space. Utilizing every square-inch to ensure optimized pallet positions was the project’s key focus.

Challenges

Facing highly-limited warehousing space as well as a storage system not designed exactly to the needs of a business is enough to frustrate any growing retail business owner. These were the challenges faced by our client, a prominent e-Commerce retailer based in Guelph, ON.

The client had moved into a 250 000 sq. ft. warehouse which initially was sufficient. But as their business expanded during the 2019 pandemic, their space suddenly become insufficient. However, they were still suffering from inefficient order picking and were not taking full advantage of their new larger space in regards to storage density. With a combination of bulk storage, an inefficient racking design, and only small amounts of selective racking, this client was utilizing a storage system that was hindering their daily operations them as opposed to it working for them.

Solutions

Due to the demand of maximized storage density for palletized loads, the team at North American Storage designed a system that could help satisfy this need by focusing on building up, rather than out.

By reconfiguring their storage system in a way that was best suited for their business, our client was able to significantly maximize the inventory held, prevent loss of valuable pallet space, while also ensuring the safety of their workers.

To accomplish all these goals, a custom storage system was designed and built featuring 28′ selective palletized storage. North American Steel’s Selective Pallet racking design installed provided an increase in pick SKU faces for most bay locations, as well as ergonomic pick levels below the knee and above the chest. As this client often moved a plethora of particularly heavy boxes, the selectivity benefit of this storage system was of critical importance.

Summary

Starting from scratch, this project ultimately was a extensive racking overhaul. Once completed, NAS was able to take over 932 000 lbs of steel and more than 28 feet of usable height, and transform this into over 20 000+ pallet positions in less than 250 000 sq. ft of usable warehouse space. Upon completion, our client benefited from substantial improvements to their storage operations in their new facility, they are able to sufficiently store all their products in a highly organized manner, while also choreographing a seamless order-picking system.

To ensure that this new storage system met their expectations, the team at North American Storage worked diligently from beginning to end and provided significant improvements to their operations, that is built to last for many years to come.

Are you interested in learning how to improve your warehouse storage operations? Please contact us here to speak to one of our industrial storage experts right away!