Whether you’re outfitting a new warehouse or upgrading an existing one, poor layout decisions can lead to product damage, hazards, and logistical headaches. At NAS Group, we specialize in designing custom racking layouts that prioritize security, functionality, and scalability for warehouse storage systems of all sizes. In this blog, we’ll walk you through five expert tips that guide our approach when designing tailored racking layouts for clients across various industries.

1. Understand Your Warehouse Operations

Every successful racking layout starts with a detailed needs assessment. When you work with us, we take the time to understand your inventory, processes, and equipment to design a solution that fits how you operate.

We assess:

- SKU size, weight, and movement frequency

- Material handling equipment (MHE) in use

- Volume and flow of inbound and outbound goods within your distribution center layout

2. Make the Most of Your Space

Optimizing space isn’t just about adding more racking—it’s about designing smart, accessible storage that works with your building and equipment. Whether you need a solution for industrial shelving or high-throughput zone, we look at both vertical and horizontal opportunities to improve performance.

We focus on:

- Ceiling height and racking elevations

- Aisle widths that match your MHE needs

- A balance between storage density and product accessibility

3. Prioritize Safety and Compliance from the Start

Safety is a top priority in every layout we design. We ensure that your racking system is not only optimized but also meets local codes and engineering standards, especially in seismic areas like BC.

Our approach includes:

- Proper clearances and load capacities

- Fire code, egress pathways to exits, and seismic compliance

- Engineered drawings and permitting

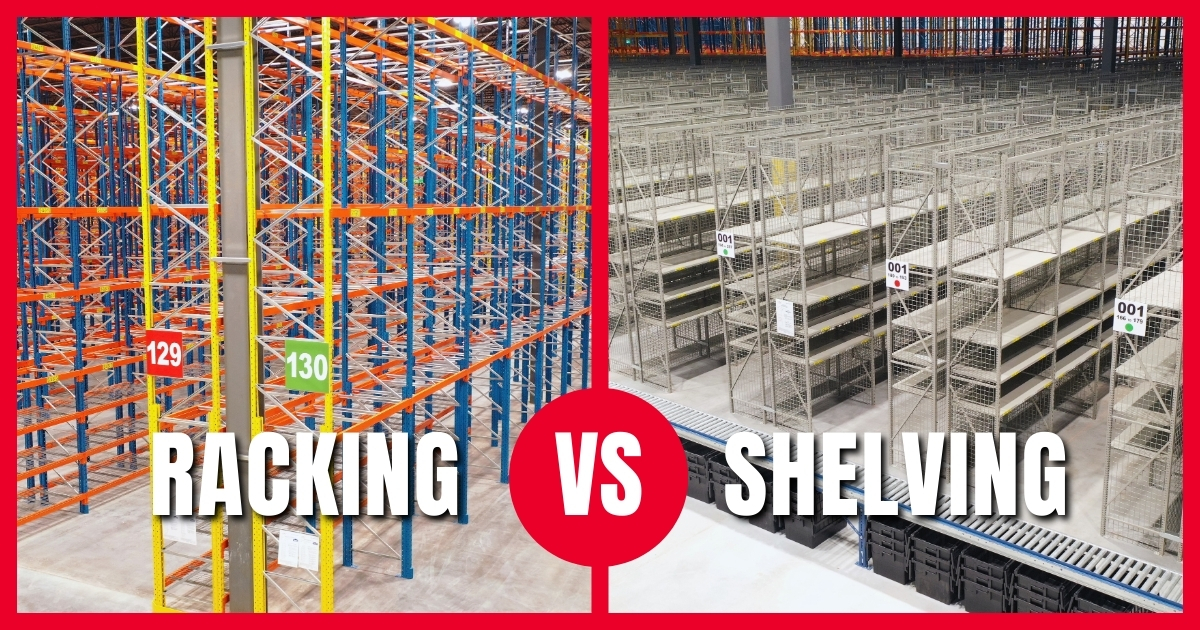

4. Choose the Right Racking System

Not all racking systems are the same, each type serves a specific need. We guide you in selecting the ideal system based on your inventory turnover, picking methods, and SKU types.

Options we consider include:

- Selective Racking: Flexible, high-access storage

- Drive-In Racking: Bulk storage with high density

- Cantilever Racking: Stores irregular-shaped and oversized objects

- Pallet Flow and Push-Back Racking: Efficient for dynamic inventory turnover

- Carton Flow Racking: Ideal for small, fast-moving items

5. Design for Future Growth and Easy Maintenance

We help future-proof your setup with scalable warehouse optimization strategies that support long-term growth.

We plan for:

- Modular layouts that can expand as your business grows

- Clear access for ongoing inspections

- Continued support and maintenance service

Let’s Build It Right—Together

A racking layout isn’t a one-size-fits-all plan—it’s a strategic investment. From consultation to installation, our team delivers engineered solutions tailored to your needs. Ready to take the next step? Contact the NAS Group today and get a free warehouse assessment.

FAQs About Racking Layout Design

Can I design my warehouse racking layout on my own?

Not effectively. Sketching a rough layout can help you visualize, but professional design ensures safety, code compliance, and operational flow. We handle the process from assessment through to installation.

Do I need permits or engineering approval?

Yes, especially in regulated areas like BC. We take care of all permitting, seismic design, and engineering for you.

What if my space has height or layout challenges?

We specialize in custom designs even for low-clearance ceilings, narrow zones, or complex workflows.

Can the racking system grow with my business?

Yes. Our solutions are modular and scalable so you can expand or reconfigure as operations evolve.