In warehousing, one size doesn’t fit all. Every industry has unique storage needs, and the right solution can make all the difference in optimizing operations, improving safety, and enhancing productivity. At NAS Group, we specialize in providing tailored pallet racking solutions that meet the specific requirements of various sectors. In this blog post, we’ll explore how our systems are designed to address the diverse challenges faced by the food and beverage sector, cold storage facilities, third-party logistics (3PL) providers, and the automotive industry.

Food & Beverage

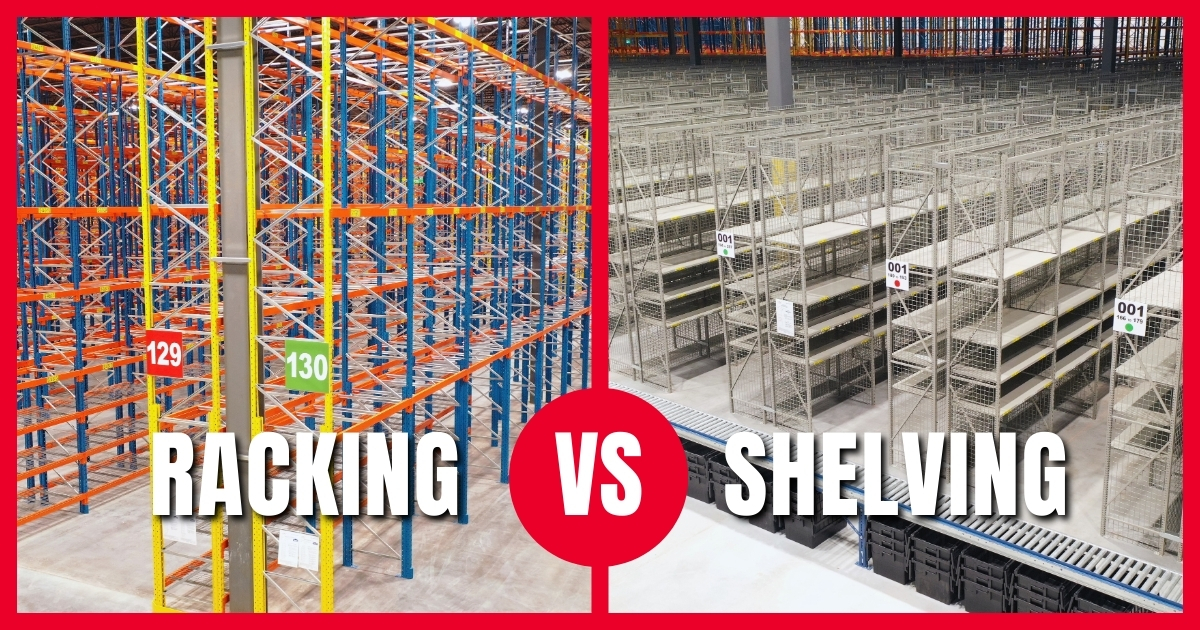

In the food and beverage sector, pallet racking systems must accommodate a variety of products, including perishable goods and packaged foods, often in temperature-controlled environments. NAS Group provides methods like selective racking, which offers easy pallet access, and pushback racking, which boosts space management while ensuring First-In, First-Out (FIFO) stock rotation. These systems are designed for easy cleaning, corrosion resistance, and compliance with health regulations. Read our case study to discover how our advanced racking systems supported a bottling company in Richmond, BC, with its expansion.

Cold Storage

The cold storage and freezer market requires racking solutions that can withstand extreme temperatures while maintaining product integrity. NAS Group offers robust drive-in racking for high-density warehousing and pushback racking that facilitates easy access and FIFO rotation. These systems are engineered to handle the unique challenges of maintaining product quality and accessibility in temperature-controlled conditions.

3PL

3PLs manage inventory for multiple clients, each with distinct storage needs. NAS Group’s solutions include selective racking for direct access to various products and shuttle cart racking that boosts storage density and operational effectiveness. These systems are adaptable to varying product sizes and quantities, providing the flexibility and scalability required in the fast-paced 3PL industry. Read our case study to learn how our selective double-deep racking system enhanced picking efficiency and inventory control for a 3PL provider in Bolton, ON.

Automotive

Efficient storage and material handling are essential in the automotive industry. NAS Group offers selective racking for quick access to parts and components, and cantilever racking for storing long or bulky items like pipes and rods. These tailored solutions support high-density storage and streamline operations, ensuring that automotive manufacturers and suppliers maintain productivity and safety in their storage processes.

No matter the industry, NAS Group offers pallet racking solutions tailored to meet each sector’s unique challenges and requirements. Our commitment to providing versatile, efficient, and reliable storage systems ensures businesses across industries can optimize their warehouse operations, improve safety, and enhance productivity.

Is your racking system holding you back? Contact NAS Group today to design a custom solution that enhances your warehouse operations and drives business growth.